Review Tss102l Ryobi Sliding 10 Inch Miter Saw

Working on your firm? Building piece of furniture? Working with woods requires a saw, and at that place are many to choose from, all with different uses and abilities. The RYOBI 12″ Sliding Miter Saw saw covers a wide gamut of needs and can find a place in the smallest and largest workshops.

Ryobi has been making quality tools for professionals and home workshops for years. From drills bits to lawnmowers they can meet just about every tool need in your shop (and generators for out of shop piece of work!). Recently they allow Disrepair Wallet endeavour out the Ryobi 12" sliding miter saw and hither is what we discovered:

What's in the Box:

What's in the Box:

- The Ryobi 12" sliding (compound) miter saw.

- 2 extension bars to extend piece of work area

- 40 tooth carbide tipped, general purpose, blade (pre-installed)

- Clamp

- Grit pocketbook

- Bract wrench

- Transmission (view online)

Specs:

- Laser line for blade line up with cutting marks, mounted off the blade and adaptable, powered by the saw, not batteries.

- At 0° a 13.5" cut width chapters

- At 0° a four" cut height capacity

- At 45° a nine.5" cutting width capacity

- 15 amp motor, 4000 rpm max

- Positive miter stops at 0°, fifteen°, 22.5°, 31.6° and 45° left & right

- Just under 27 lbs.

Ryobi 12" Sliding Miter Saw Review Breakdown

Setup and Build:

The saw is well packed in Styrofoam and unpacks easily with a second person. It'due south snug, and then information technology helps to have a second person either help remove the saw from the box, or concur the box down while yous lift out the 27lbs of metallic and machine. There is a conduct/lift handle well placed dead-eye on top of the saw.

The work slice back up wings attach from the underside with one screw each, and while you can do this yourself, proceed that 2d person around for it. You don't really want to remainder 27lbs of sharp saw teeth by yourself while trying to put in a small-scale screws. The front of the saw has an adaptable foot under the miter lock that at first I thought was just 'nice', but realize that it was really of import one time I tried sliding the saw head forrard. There is a lot of weight to the head and having that foot adjusted and locked down isn't just 'nice' it is a necessity.

The saw has a lock to keep the blade down, and some other to keep the blade caput from moving forrad. And as well a miter lock for controlling the angle of the bract. I checked the bract for square when I got information technology and information technology was already lined upwards for me. There are adjustments that tin exist made if it is off. But one thing I noticed is that if it is off for miter and you have to adjust it, and then the positive stops that are ground into the metal won't be right for you either. It isn't a problem every bit long every bit your saw is foursquare like mine was, but check it when unpacking. For the bevel (the compound of a compound miter cut) the aligning has a positive stop at cypher, and you lot can reset zero by a few degrees if needed with an arrow held downwards by a screw which is a good design.

The saw has a lock to keep the blade down, and some other to keep the blade caput from moving forrad. And as well a miter lock for controlling the angle of the bract. I checked the bract for square when I got information technology and information technology was already lined upwards for me. There are adjustments that tin exist made if it is off. But one thing I noticed is that if it is off for miter and you have to adjust it, and then the positive stops that are ground into the metal won't be right for you either. It isn't a problem every bit long every bit your saw is foursquare like mine was, but check it when unpacking. For the bevel (the compound of a compound miter cut) the aligning has a positive stop at cypher, and you lot can reset zero by a few degrees if needed with an arrow held downwards by a screw which is a good design.

The left work piece wing has the ability (and need) to slide the elevation half further to the left (as shown above). I say need, because if you do a bevel cutting you'll cutting through the fence if you lot don't motion it. I had a friend do that in one case, and always since I just keep mine positioned to the left.

And there is a surprise lock: the dado lock (the funky spring loaded screw pictured above). Aye. I'g certain they call it something more clinical similar 'blade depth control, only 'dado lock' sounds libation to me. Y'all tin can set the blade depth with this special lock on the right paw side behind the motor, what's more, there is a lever that engages the lock or not, and so you tin can prepare a dado depth, employ it, then go back to miter cuts and when you render to dado cut? Boom, information technology'south already set from terminal time. Yous'll need to space your piece of work out from the debate 2.25″ to create fifty-fifty depth of cut on your datos, but in my opinion this is a really cool selection and I can't wait to apply information technology. I've avoided datos on my table saw considering I don't have a dato blade and I don't like the not seeing the cut I'm making. I can't remember of an easier way to cut datos without a correctly setup table saw.

There are holes behind the fence for the clamp on both the left and right sides of the saw head. At outset I didn't like the clamp, it is a knurled rod and doesn't look like it would be that secure in the hole, just later using it, I liked information technology and information technology works as expert as any other clench I've used. I'll note merely that it doesn't work great in the correct-side hole, if you put information technology where you think you should, it gets in the mode of the saw caput when you lot bring it downwards, so you have to swing information technology over the loftier spot on the correct side of the fence. To me, that'southward poor planning. Y'all can hold a piece of wood on the left with your left hand, and bring the saw head downward with your correct hand, this means yous need to clamp on the correct. Only the clamp works a lot better on the left. I'll say it isn't just awkward to concord the forest on the right and cutting with your left hand, information technology is downright dangerous and I don't advise it.

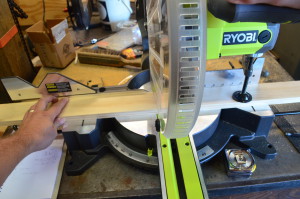

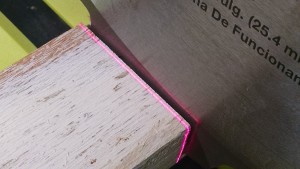

The laser that lines up your blade to your cut mark on the woods is powered by the saw, not batteries, then it isn't going to run out at a bad time. It is as well mounted on the saw head and isn't function of the blade locking washer. This is skillful and bad, good because information technology is adjustable with a skew aligning to make it parallel with the blade. Mine was lined up with my blade for cut, merely if yours isn't, There is no adjustment for moving the laser line closer to, or further from, the cut. At first I didn't recollect mine lined up because when I checked it, I had the blade down against the work slice, just it does line upwards. What'due south the outcome? Well, as you can see by the photos above, the line moves to the left as you bring the saw downwards. When the saw head is fully up my laser is lined upward, merely when I bring it down, it moves to the left. I have to trust information technology will cut where the line was, and not where the line moves to. It works, just that makes it a chip abrasive because I can't cut a lath twice to make information technology longer and I have trust bug with ability equipment sometimes. I've read other accounts online with having a problem lining upwards the laser in different ways. You'll want to cheque yours and really work that skew aligning with a foursquare until you know it is right or isn't. I've found near light amplification by stimulated emission of radiation alignments to have similar problem, then it isn't unique to this saw, but it is a disappointment.

Ability and cutting:

15 AMP motor, 13.5" cut width, four" cut elevation but I wouldn't try to cut a 4×thirteen.5 axle. You could, merely information technology might crush you trying to get it up on the saw. The manual states nominal cut sizes of 4×6 and 2×fourteen every bit the max cutting sizes, that's because nominal isn't bodily. A 4×4 is iii.5×three.5 and a ii×14 is 1.75x 13.5. I measured the saw chapters to be an bodily width of 13.5" and an actual height of 4". The transmission also states that for cutting ¾" baseboard against the debate, the max cutting summit is 5.five".

Ease of Use:

This saw is a beast and for what it does, insufficiently small. My father has a 10" rip saw he bought years ago that takes up a ton of room and isn't portable. I've got a 10" compound miter saw (with no slide) that I consider meaty and very portable. This is more portable than my begetter's rip saw, or say, a table saw, merely I feel one time y'all have it setup up, you aren't going to want to move it all the fourth dimension. The carry handle is well placed to pick the saw up, but I wouldn't want to deport this beyond a task site on my own. This is a ii person elevator in my opinion, considering of weight and bulkiness, and abrupt pointy teeth that can cutting yous up. That and you don't want to adventure dropping this and knocking something out of alignment. One time at that place, information technology'll do the task and I call back that the weight/awkward carry is just a problem of this blazon of tool. It isn't meant for moving day to day, although you could if you wanted to I suppose.

The "D" handle is nice, and compared to my 10" saw from another maker, I like the Ryobi better. Information technology is a smooth pull down, and the activity on pulling the saw forrad is shine as well. I also similar that I don't have to slide back through my work, I tin can elevator the blade and slide it back as to not take chances nicking the wood with the blade while it slows down.

When you engage the trigger the saw leaps a fleck just not uncontrollably or unexpectedly. The bract guard reminds you well to keep your easily, artillery and confront away from the blade and looks like information technology does an adequate job of protecting all the way down with your cutting without getting in the way of the cut. It won't finish yous from getting to the blade if you really try, just I did brush it lightly once while moving likewise fast and I'yard glad it was there.

The dust bag does a proficient job at collecting dust, just is likewise small-scale for practical apply. You're cutting with a 12" blade!

To test the saw I built a table and was cutting 1×6 poplar for the top boards, something a 10" saw can't do with-out flipping over the piece of wood, and 4x4s for the legs, something my ten" also can't practice. Cutting more than wood = more saw dust. Going to cut a few 2x4s? No problem. Going to do dado cutting or 4x4s all day? You'll demand to hook up the vacuum. The grit port is a standard 1.v" connection so they brand that easy.

To test the saw I built a table and was cutting 1×6 poplar for the top boards, something a 10" saw can't do with-out flipping over the piece of wood, and 4x4s for the legs, something my ten" also can't practice. Cutting more than wood = more saw dust. Going to cut a few 2x4s? No problem. Going to do dado cutting or 4x4s all day? You'll demand to hook up the vacuum. The grit port is a standard 1.v" connection so they brand that easy.

The manual and website talk about an electric restriction on the saw, just I haven't noticed it. The blade spins for 4 to 4.v seconds (I timed it) subsequently you let go of the trigger. Possibly that's what they're talking about and I'm just used to it on all my saws so I don't think it is that quick. I estimate I was expecting it to stop in 1-two seconds.

Negatives:

As mentioned in a higher place…

- The laser adjustment/placement moving as the saw caput comes downwardly.

- The size of the dust bag – modest outcome, fixed with a vacuum.

- Clamping location/fence on the right side.

- The type of adjustment for the miter cut will render the positive stops useless if yous need to arrange information technology at all.

- Zipper of the extension wings being secured on the bottom, it would be nice to have the screws that hold them down enter from the front through the frame. Then you wouldn't need to tilt or lift the saw to remove or attach them.

None of these are deal breakers for me, even at $299, merely they were all stand-outs to me the first time I used the saw.

Value:

At $299 I don't recall you'll notice a amend built 12" compound miter saw, much less, one with a slide for wider boards. I've lived with and used a non-sliding 10" saw for 14 years and I've gotten all my projects done, but I've had to be more creative with how I did sure things, or accept certain limitations. In building my table, I didn't just purposely use larger lumber, I wanted to use larger lumber from the first in the design stage (I've spent too much time on pinterest). None of these cuts would have been possible on my ten" not-sliding version. If you are going to buy a compound miter saw, and if you are putting together a workshop, you are going to buy one eventually, I really retrieve that this should be on the superlative of your listing to bank check out. The negatives I found were not anywhere close to a deal breaker for me. Information technology is bigger than my 10″ non-sliding compound miter saw, simply I say make the room.

The only other improvement I tin can think to make is to get a finer toothed bract for it. The blade it comes with is fine for framing, but it isn't super clean on finish work and I don't want to tape up all of my cuts earlier I make them to prevent splintering. Information technology worked for the tabular array, but a effectively tooth blade will reduce sanding in the time to come. If I was using this on a job site I'd stick with the stock blade, but I take don't accept to do that in my workshop.

Purchase Now: $299 or learn more than at:RyobiTools.com

RYOBI 12" Sliding Miter Saw - Tool Review

The light amplification by stimulated emission of radiation setup was unexpected, it'south heavy to go out of the box, the dust bag is small, only I'yard very happy with the saw (and with my new tabular array!). It cut the everything just the way it should and has options I've never considered on a saw like this (dato adjustment). For the home user in that location is no reason to spend any more coin. For the builder this meets your needs for the job site at an fantabulous cost.

The Good

- HUGE cutting chapters

- Powerful

- Unexpected Datos!

The Not So Skilful

- Right side clench

- Size of the dust bag

rodrigueztwentone.blogspot.com

Source: https://bustedwallet.com/ryobi-12-sliding-miter-saw-tool-review/

0 Response to "Review Tss102l Ryobi Sliding 10 Inch Miter Saw"

Post a Comment